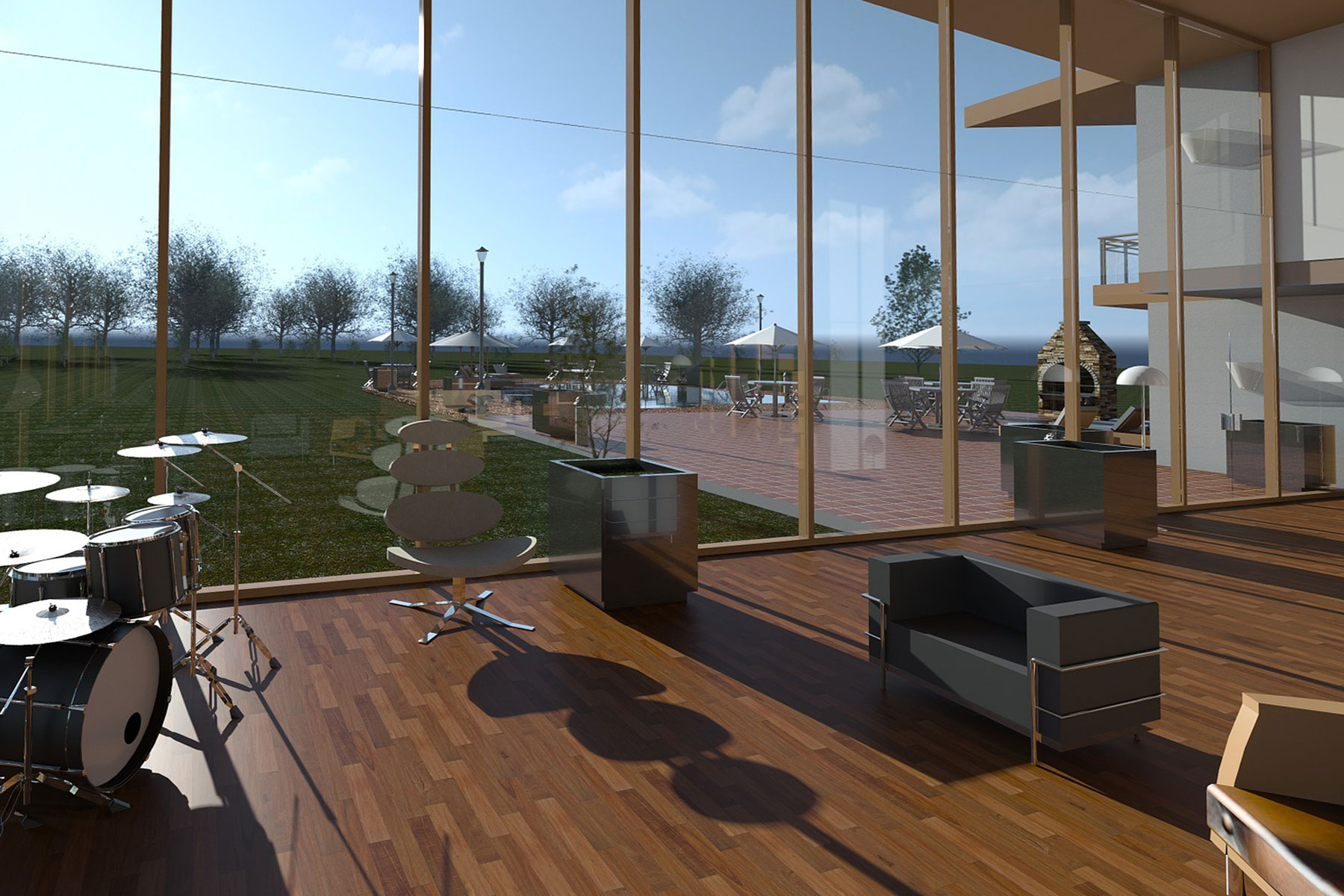

WE VALUE DESIGN, INNOVATION AND QUALITY ABOVE ALL

WE HAVE A RANGE OF PRODUCTS SUITABLE FOR YOUR BUSINESS OR YOUR HOUSE!

We work mainly with ALUMINUM and PVC, but also with INOX, IRON, GLASS, etc…

Our main goal is to make a difference in this market sector and to offer our clients a viable and attractive option regarding the delivery of the projects.

We know that it is fundamental to grow in a sustainable way, with dedication, rigor and professionalism above all, always guaranteeing the satisfaction of our clients and the creation of a solid and trusting relationship.

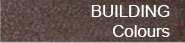

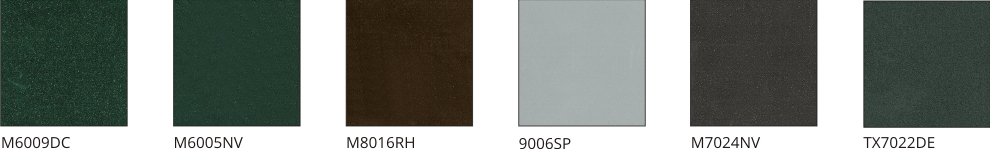

WE WORK WITH AN UNLIMITED COLOR RANGE

POWDER COATING

The powder coating process consists of covering the aluminium with a layer of organic coatings. The painting of aluminium with powder paint is made by way of electrostatic removal and its subsequent polymerisation in an oven at temperatures that reach up to 200ºC. This process converts it in to a highly resistant surface resistant to severe atmospheric conditions.

The powder coating of the profiles is another of the aluminium surface treatments that, as well as protecting it even more from natural corrosion, allows it to attain an unlimited variety of colours with which it answers the needs of the architectural professionals.

Colour is fundamental when creating harmonious aesthetic assemblies for architectural projects. In this sense, we offer an extensive colour range that stretches from the classical finishes, gloss or matt, moving to special coatings with rough textures, imitation of noble materials such as timber (pine, oak, chestnut, teak, sapelly, cherry, walnut…) up to anti-bacterial finishings comprising of silver ions adhered to a completely inert and natural resin, that prevents the growth and migration of bacteria, virus, mold, fungus and septic matter.

ANODISING

Anodising is the surface treatment that is capable of obtaining an aluminium oxide coating (AI203) on the base aluminium surface by way of an electrolyctic process consistent in producing the circulation of a continuous current through an electrolyte with an acid base.

With this process, an artificial increase of up to 1000 times the thickness of the natural aluminium oxide coating is achieved, obtaining great protection against corrosion and abrasion. Its own characteristics of this material with regard to resistance and durability are increased considerably using this surface treatment, converting it in this way as an ideal material for building enclosures in coastal zones and subject to hard climatic conditions.

We have available an extensive anodising colour range: bordeaux, blue, green, ivory, black, grey, bronze, inox (stainless steel), champagne, gold, natural, copper and acier, that once more demonstrates its innovative character. All these colours can at the same time be presented as different finishes after subjecting the profile to mechanical surface treatments, and therefore obtaining matt-grain, rough brushed, bright, brushed, polished, re-polished or combinations of any of these finishes.